12 April 2021

How to deal with an accidental flocculant spill?

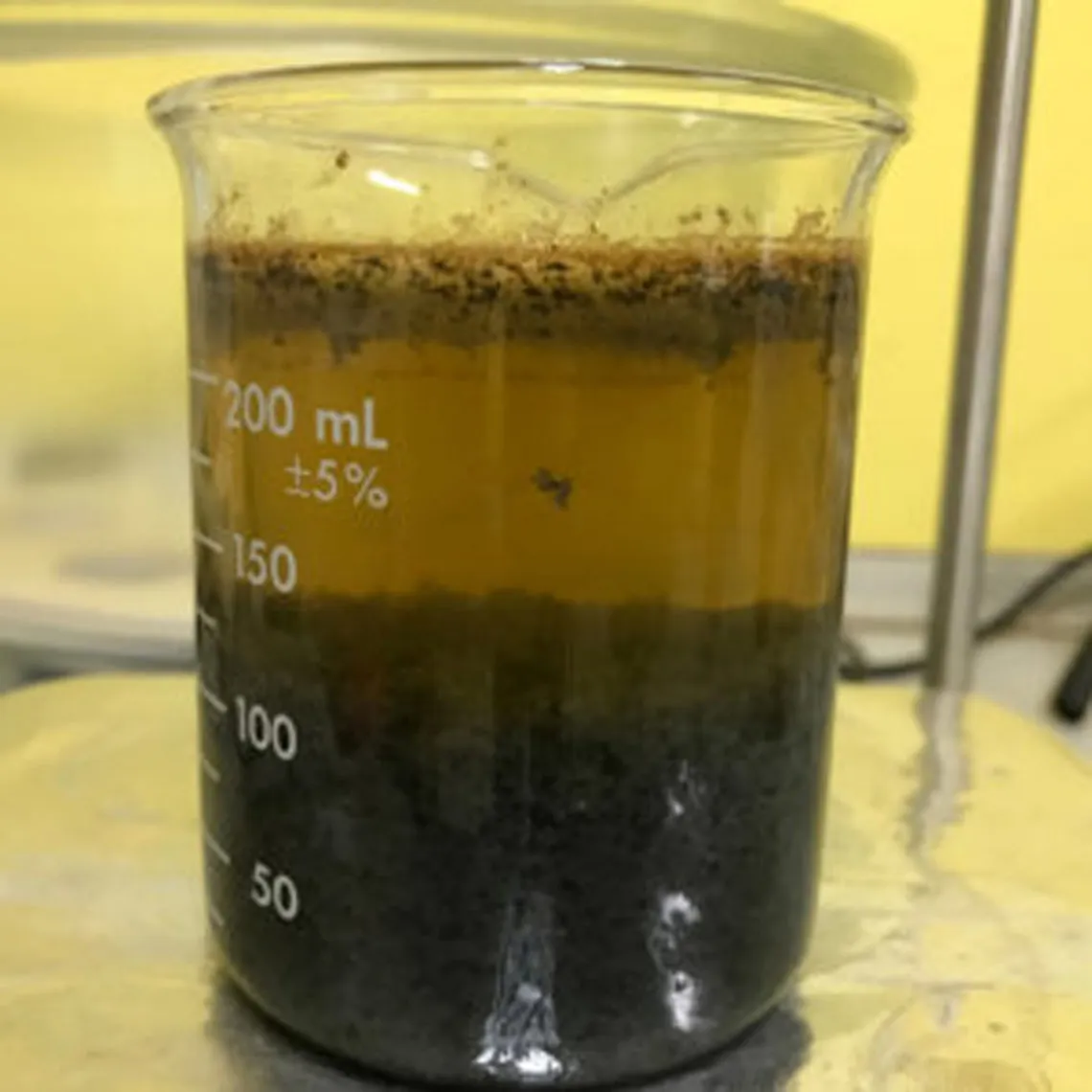

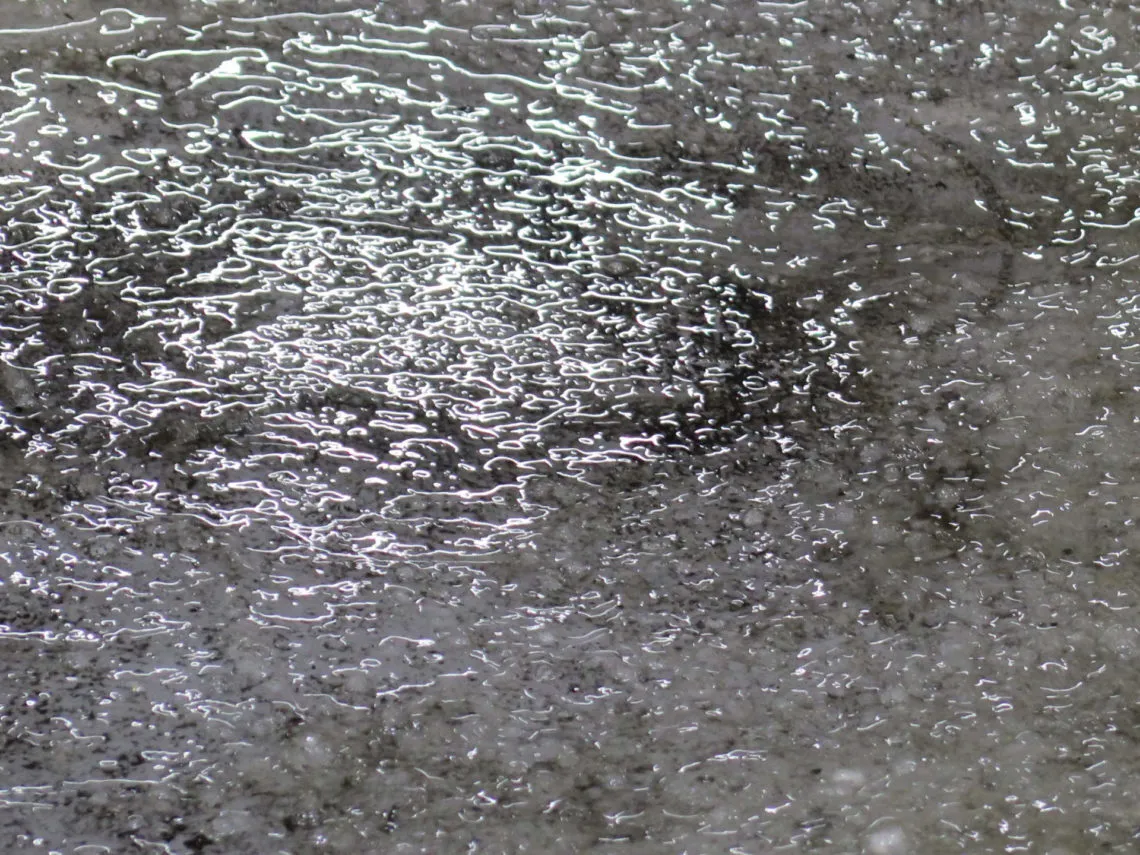

Flocculants are polymers that are mainly used in the treatment of wastewater containing suspended particles. During a spill, the ground surface soiled by flocculants becomes extremely slippery. If cleaning is not carried out perfectly, mere contact with water can cause a serious fall hazard. In this article, discover the nature of flocculants, where they are used and our spill management advice.